Many organizations use plastic products on a daily basis but they don’t manufacture them necessarily. Many plastic manufacturing companies produce plastic components but they also do not provide complete service to create and distribute your products. That is why it is very much important to select top plastic manufacturing companies and nicely maintained plastic products suppliers as well for you for the development of your business. It depends on you whom you will trust with your expensive business products.

The best plastic manufacturing companies should have the following qualities to look out for:

Well, communication- A plastic manufacturing company should go for the staff to have good communication skills. Their team should communicate clearly and passionately. A company should provide you a brief description of events that happen during the manufacturing process. Two things you must keep in your mind-

- You should be able to connect and contact the manufacturer to receive regular updates regarding your plastic design creation.

- The company should communicate with you in ‘industrial terms’ while you are going through the order placement process.

The manufacturer must be responsible, professional, and all-time available for you to include you as a major aspect of the entire development procedure.

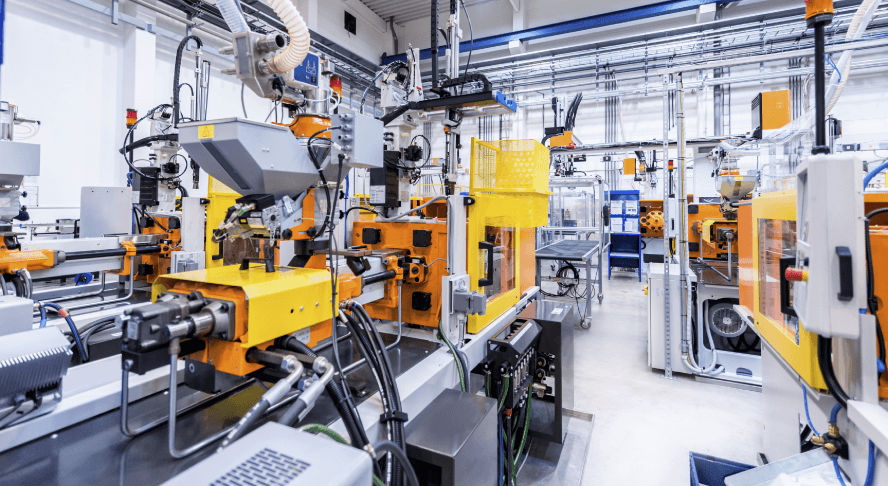

- Local Manufacturing- You can go for a manufacturer who does not outsource and manufactures locally. It provides a competitive advantage compared to others. Experienced engineers and in-house mould makers help customers to get full solutions according to their requirements. It also helps you to get in touch with your manufacturer easily. You will get a better effort from your manufacturer for the betterment of your products.

- Experience- Experience is one of the most important authentications of a manufacturer’s capability to mould a perfect part. When you are searching for a dependable, experienced plastic moulding manufacturer, make sure to enquire about their working experience and how vast they have been working with their expertise.

- Quality of the plastic products- Selection of the plastic materials, plastic part design, and failure analysis can appear to be a complex subject to you. It happens especially with customers who are unfamiliar with polymers. If the materials have any one of the following remarks then it can be defective:

- Low chemical resistance

- Degraded molecular weight

- Increased the probability of stress cracking during use

If the plastic sheet is extruded unnecessarily it may have residual stress. So it is very much essential to choose a plastic distributor who uses quality materials.

- Financial condition- Plastic manufacturers’ working field depends on financial stability. Companies with an unstable financial background may be unable to produce products and collect inventory properly to meet your needs. Plastic distributors and manufacturers who are financially stable can create a better experience for you.

Remember, it is important to choose a financially stable plastic manufacturer who can support your business with the best products and services. They can provide technical support when needed and multiple sales channels for expanding your business area. Moreover, a good plastic supplier can be an excellent resource that will allow your company the freedom to grow.